Home Lab Reflow Plate

Soldering circuits by hand is a PITA and, while it's totally viable for single boards etc, reflow assembly is a truly blissful step away from the banal.

So, yrs truly is here to spec out a reflow system. In the open source these are commonly done with modified toaster ovens, but I'm attracted to the 'hot plate' method: i.e. Skillet Reflow. Here, we (one sided only) just put boards on a hot plate, and run that plate through a temperature cycle. Since boards are mostly conductive and parts live on the surface, the local plate heating seems to make a lot of sense.

Here's a video of the principle.

I think the move is to use a Silicon Heating Pad (commonly used in 3D Printer beds), which are available up to high wattages (~1350 in one I am checking now) but to calculate this properly I need wattage / sqm: area power. And to calculate that against power req. to bring aluminum plate of whatever thickness up to temperature... at some specified rate, which (?) I think is some simple ish spreadsheet maths.

Unless things look like they come close, I will probably do this without looking at losses from i.e. dissipation into free air, but this will be a big hole. I will insulate the thing, but not exceptionally well.

Calculating Power Requirement

OK, I need to know, for some set thickness of aluminum, how much power I need to raise its temperature fast enough to reflow properly.

- Aluminum has a specific heat capacity of 0.9 J/gK

- joules per gram-degree

- that's how many joules needed to raise one gram by one degree c

- so, given watts (joules/s), I can calculate a rate deg/s

- From temperature curve in Solder Paste SMD291AX250T5-ND datasheet, in its steepest ascent, wants 85 deg rise over 90s, for 0.94 deg/s: nicely rounds to 1deg/s.

- Aluminum has a density of 2.7g/cm^3

I've made a little spreadsheet. I've DOF in thickness and can set Watts / Square Meter by the parts I can find.

I'd like for the plate to be around ~ 1/4" thick, just to be substantial enough to stay pretty flat during the process. If I want to get there, I need to target around 16kW/sqm. Since I'm not counting losses, of which there is a great deal, I should adjust up to aim closer to 20kW/sqm. With 1500W out of the wall, I can only do 0.075 sqm, or roughly 275mm square.

Finding the right part is just a trick... Around the minimum size I'd like to build this is 150x150mm, which fits a 3x3 grid of NEMA17 drivers.

MPHKH-150-150-V100-W500 Misumi $116 Plate Heater 22kW/sqm

It looks like the Misumi plate is about as best as it'd get. I can knock down my thickness desires and settle for 3/16" (almost 5mm). However, looking at 'the market' for plate heaters, I'd say the Misumi part is, although expensive, the best way to do good reflow. I'll pick that, and get a matching 6x6" ALU plate. The thru holes (nice) on the plate are 6mm, so I'll fit M5 legs and washers to clamp the plate down, with lock washers.

Parts

To control this, I'm going to pick up one of these projects.

The heating plate of choice is a Misumi component,

MPHKH-150-150-V100-W500 Misumi $116 Plate Heater 22kW/sqm

I need an SSR, SSRx3

Various hardware:

- 6x6" 0.190" Cold Rolled Alu Sheet 89015K275

- M5 SHCS x30 91292A192

- M5 SHCS x10 91292A124

- M5 Nuts (not nylocks) 91828A241

- M5 Lock Washers 92148A170

- M5 Washers 93475A240

For the enclosure, I'll want some rigid insulation and reflective tape. Making a box with this will be easy, just cut & tape together, nothing fancy.

- Hot Tape 76035A66

- Reflective Rigid Insulation (unfortunately, this is a 5-pack)

Assembly, Test

OK, I went through a few plate thicknesses - definitely the move is to go as thin as possible while still retaining some flatness. At the moment I'm working with 1/8" thick 6061, but could probably go thinner.

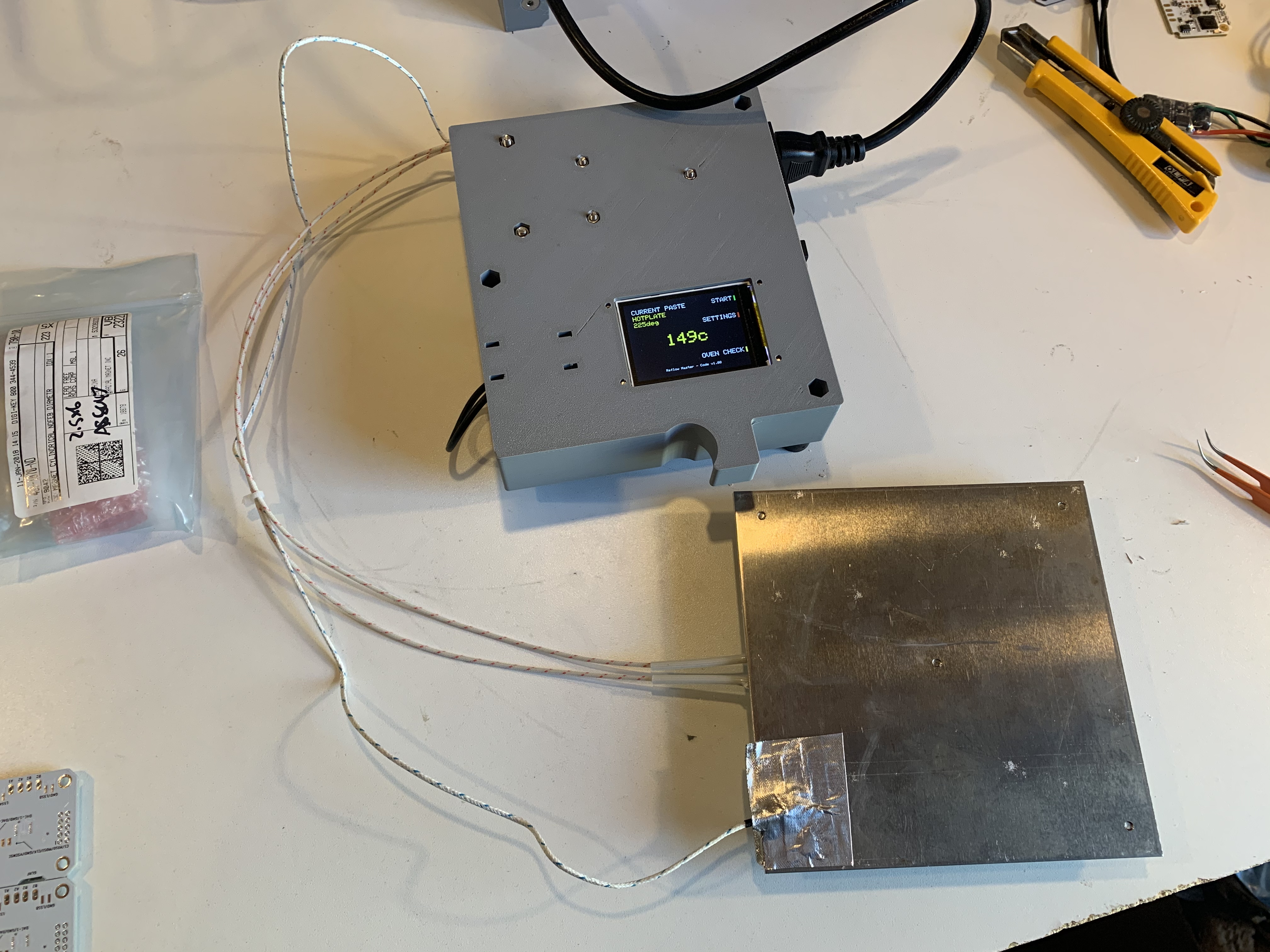

I mounted the reflow control bits in a little chassis, and just drilled & tapped the plate to mount the heating element underneath. The four corners have longer M5 BHCS, that serve as tiny feet for the plate as well.

I added a new profile to the ReflowMaster code, you do this just by adding some lines to the source and re-flashing the board.

float baseGraphX[5] = { 1, 180, 240, 350, 400 }; // time

float baseGraphY[5] = { 25, 150, 175, 235, 25 }; // value

solderPaste[0] = ReflowGraph( "HOTPLATE", "Ramp to 225 Surface Temp", 225, baseGraphX, baseGraphY, ELEMENTS(baseGraphX), 360, 450 ); // last two: fan time, off time

float baseGraphX1[4] = { 1, 100, 210, 250 }; // time

float baseGraphY1[4] = { 25, 175, 235, 25 }; // value

solderPaste[1] = ReflowGraph( "HP WARMED", "Fast Early Ramp", 225, baseGraphX1, baseGraphY1, ELEMENTS(baseGraphX1), 260, 300 );